Recorder Span

Often,

the end user judges the success of the project by what the chart recorder

indicates. The span of the chart may seem a trivial detail, but experience

has shown it is sometimes the most important but under-specified variable

in the project.

Often,

the end user judges the success of the project by what the chart recorder

indicates. The span of the chart may seem a trivial detail, but experience

has shown it is sometimes the most important but under-specified variable

in the project.

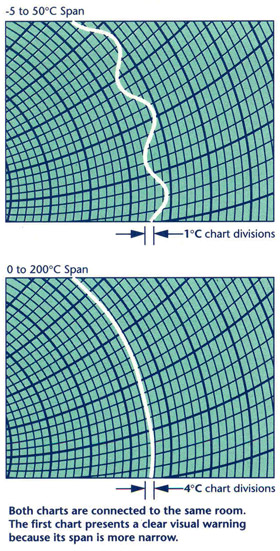

The charts at left both record conditions of the same room at the same time--only the chart span is different.The room is not controlling at a uniformity of ±0.5ºC. The upper chart shows the problem clearly. The lower chart completely obscures this inadequate performance.

The upper chart comes from a recorder typically supplied with environmental rooms. It records temperature from -5 to 50ºC. The lower chart comes from a recorder typically supplied for cold storage rooms, and it records temperatures which span the range from 0 to 200ºC.

In general, the architect should specify the chart range which covers the range of interest most narrowly--otherwise it will be difficult to validate the supplier’s performance.

For an environmental room, it is also important to specify the accuracy of the chart recorder as well as its span. Most room designers require a recorder accuracy of ±0.5% of span.

A recorder with a -5 to 50ºC span, and an accuracy of ±0.5% of the span will indicate temperature changes with ±0.275ºC (which is 0.5% of the 55ºC span).

In contrast, a recorder with a 0 to 200ºC span and an accuracy of 1%-of-span

can only show temperature differences of ±2ºC. Such a device would

not be capable of properly recording room performance if the uniformity specification

were ±0.5ºC.

Ventilation Air

Heat

and moisture loads from ventilation air can be quite significant, affecting

both construction and operating costs of environmental rooms. In general,

the architect is well-advised to use the minimum amount of ventilation air

whenever possible.

Heat

and moisture loads from ventilation air can be quite significant, affecting

both construction and operating costs of environmental rooms. In general,

the architect is well-advised to use the minimum amount of ventilation air

whenever possible.

Table 2.2 of ASHRAE Standard 62-1989--Ventilation for Acceptable Indoor Air Quality--recommends a minimum ventilation air quantity of 20 cubic feet per minute (cfm) per person in laboratories.

This ventilation rate is appropriate when the space is occupied continuously. When the room has intermittent occupancy peaks of less than three hours duration, the standard recommends continuous ventilation of 20 cfm per person for the average occupancy during working hours, or one half the maximum occupancy--whichever is larger. For example, a room occupied by two people intermittently requires at least 20 cfm continuous ventilation, but 40 cfm is not necessary.

Cold storage rooms are not addressed in the standard, but such rooms are not generally ventilated unless either hazardous vapors or people are present in the storage areas continuously. This another reason that cold storage rooms are less costly than environmental rooms.

Specific processes may require more than standard ventilation. Where the end user is unsure about special ventilation requirement, the manufacturer of the process equipment will often provide guidance.

Beyond that, the end user can consult the references listed in ASSHRAE Standard 62 as well as the 1986 Industrial Ventilation--A Manual of Recommended Practice, published by the American Conference of Governmental Industrial Hygienists.

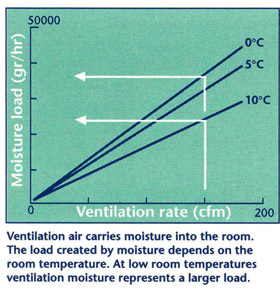

In all cases ventilation air means larger mechanical systems, but cold rooms are more affected by increases in ventilation than rooms at ambient temperature. This is because larger moisture loads can lead to loss of temperature control during defrost cycles.

Moisture in the ventilation air condenses on the cooling coil. When temperatures are low, the condensate freezes. Coil capacity is reduced and it becomes necessary to defrost. Increasing ventilation from 20 cfm to 50 cfm of unconditioned air will increase the number of defrost cycles from 4 to 8 times per day. Each cycle requires about 5 minutes for completion. In some cases, this may not matter. In others, 40 minutes per day of out of control conditions may have serious consequences.

The problem can be solved by using a desiccant dehumidifier, which

will increase the room costs by 15 to 30%, depending on the volume

of ventilation

air and

its moisture content.

| Environmental

Rooms | Dry

Rooms | Clean

Rooms | Archival

Storage Vaults | |

Harris Environmental Systems, Inc. • 11 Connector Road • Andover, MA 01810 |

| tel: (978) 470-8600 • fax: (978) 475-7903 |