D/H Series Custom Dehumidification Systems

D/H Series - The Reasonable Alternative For

Critical Humidity Control Applications:

D/H Series - The Reasonable Alternative For

Critical Humidity Control Applications:

In order to obtain improved product consistency, high yields and reduced

process downtime, manufacturers and users of hygroscopic products and moisture

sensitive materials  recognize the importance of accurate humidity control.

Traditional HVAC systems are not designed to deliver consistent dewpoint

control below a 50ºF dewpoint, thereby necessitating that a packaged

dehumidification system be provided. The Harris D/H Series Custom Dehumidification

Systems are designed to meet your needs for dewpoint and temperature control,

within the space limitations and budget constraints of each project.

recognize the importance of accurate humidity control.

Traditional HVAC systems are not designed to deliver consistent dewpoint

control below a 50ºF dewpoint, thereby necessitating that a packaged

dehumidification system be provided. The Harris D/H Series Custom Dehumidification

Systems are designed to meet your needs for dewpoint and temperature control,

within the space limitations and budget constraints of each project.

Since each system is tailored to meet your application, a Harris D/H Series system provides many benefits:

- Lower operating costs than field built up systems.

- Close tolerance humidity control with systems maintaining tolerances as tight as ±0.5 gr./lb of dry air.

- Improved product consistency and higher yields increase profitability for pharmaceutical, lithium battery and chemical processing applications.

- System designs to deliver air as dry as a –76ºF dewpoint.

- Pre-piped and pre-wired system. Simplify field installations and reduce coordination headaches.

- The Harris “Single Source Quality Guarantee” provides the most comprehensive warranty available.

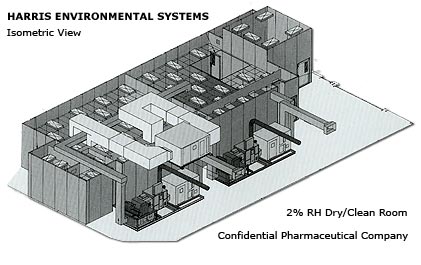

- Our capabilities can be expanded to include turnkey installation of ductwork, controls, electrical power wiring and full dry rooms where required.

- Previous experience includes D/H Series systems installed with our dry rooms in North America

The Harris D/H Series Design Philosophy

Very few humidity problems can be solved by simply buying a dehumidifier

and ducting it into an existing room. For optimal humidity and temperature

control, a packaged, custom built dehumidification system complete with

cooling, filtration, face and bypass control at the dehumidifier and integration

of controls is necessary.

Although we have several standard D/H Series systems, our philosophy is to approach each application from the viewpoint that carefully selected components and controls must be integrated into a system configuration that:

- Meets or exceeds the controlled humidity and temperature requirements

unique to that application,

- Fits within the building physical constraints;

- Is affordable and within reach of clients’ budgets.

Key Factors in D/H Series System Design

The design of each D/H Series system begins with

a complete understanding of seven key variables:

- Required temperature and humidity control levels.

- Internal moisture load from personnel and product in the controlled space.

- Internal sensible heat load.

- Room exhaust and make up air requirements.

- Room infiltration loads from door openings, conveyers and wall joints.

- Room pressurization level required.

- Space and services available for D/H Series systems.

Personnel loads, product load and make up air requirements are usually the critical design factors which dictate the size of the dehumidification system required to meet your specification.

Personnel Load

Our experience in dry room system design and construction has

enabled us to redefine the actual moisture load generated from people in light

assembly applications rather than accept outdated industry standards. Once

we define the room temperature setpoint, quantity of people, and type of

work to be completed, we can quickly calculate the expected moisture load

from personnel in the controlled space.

Product Load

Defining moisture loads from products can be difficult since the moisture

load is a function of the quantity of product and the differential between

the entering product moisture content and the desired final product moisture

content. Additionally, evaporation loads from wet processes must be calculated.

Process Exhaust/Make Up Air

Process exhaust is critical to the design of each system. Sufficient

make up air to provide room pressurization and allow process exhaust must

be included. Additionally, many of our D/H Series systems utilize a purge

desiccant dehumidifier for reactivation air to reduce energy consumption

and provide the lowest possible dewpoints. When utilizing dry air for reactivation,

this increases the system make up air requirement.

QUALITY HARRIS CONSTRUCTION

Double Wall Plenum Design

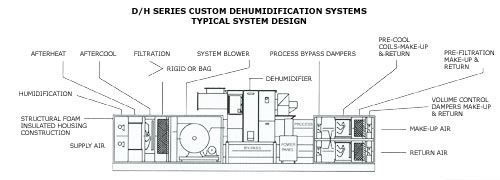

Each D/H Series system is designed with a preconditioning

plenum module, the dehumidification unit, and final conditioning plenum module.

All plenum housings utilize our double wall aluminum panels with a 2” isocyanurate

foam core to provide vapor tight construction. The D/H Series double

wall plenum design provides superior insulation (R-16) when compared to fiberglass

or Armaflex insulation without the hardening and adhesion problems encountered

when these materials are applied to sheet metal plenums. Our double wall

design also meets FDA GMP standards for air handlers used to in clean

rooms or validated facilities.

Desiccant Dehumidifier

The desiccant dehumidifier is selected based on moisture removal requirements

and only dry desiccant units using HPX, lithium chloride, silica gel or

molecular sieve desiccant are used. Dehumidifiers can be reactivated with

electric, steam or natural gas and range in capacity from 150 CFM to 15,000

CFM.

For ultra dry applications, rotating desiccant wheel dehumidifiers shall be utilized because of their ability to achieve a delivered air condition of .047 gr/lb or dry air (-76ºF dewpoint) while utilizing less reactivation energy than other desiccant systems.

A welded aluminum discharge duct from the desiccant dehumidifier connects to the final conditioning plenum module. Components with this module include fans, cooling coils, filters (including HEPA filters), heating coils, steam humidification, and heat reclaim coils. Fig. 1 illustrates a typical D/H Series system.

System Configuration Based on Available Space

Where floor or roof space is available, the D/H Series system will

be built on a continuous skid to ease installation and system design. When

space limitations preclude utilization of a horizontal air flow skidded

system, Harris is well versed in designing vertical or U-shaped D/H Series

systems to fit within tight mechanical rooms.

Refrigeration System Design

Each D/H Series system can be pre-piped at our factory to either direct

expansion cooling coils or chilled water coils depending on your available

services. Integration of cooling coils with air or water cooled condensing

units can also be provided for each D/H Series system. As a leader in quality

industrial refrigeration system designs, including cascade systems, two-stage

systems and biomedical process cold rooms, Harris refrigeration systems

provide a level of quality and system integration not available from other

package system manufacturers.

Precision Humidity Control

Although many air handler manufacturers can select coils, fans and

filters, our background in process controls allows us to offer state-of-the-art

industrial controls for temperature, humidity and pressure. Each D/H Series

system will include a control panel, which can include any of the following

components.

- PID microprocessor controls for temperature and humidity assure close

tolerance control.

- Humidity sensors using either frosted mirror dewpoint sensors, aluminum

oxide current inducing sensors, or thin film capacitance electronic sensors.

Final sensor selection is based on humidity tolerances required.

- Complete DDC “smart controls” systems with touchscreen access for data monitoring, control and remote PC data acquisition. With a modem hookup, Harris can service each system from our factory.

Since you cannot run a mechanical system without proper controls, Harris believes our control expertise should be offered with each D/H Series system. This includes:

- Setting of the D/H Series system in the proper location.

- Installing all refrigeration piping from a remote condensing unit to

the system piping headers.

- Completion of remote sensor and control wiring for temperature and humidity

to all controls provided.

- Installation of ductwork from the mechanical system to the conditioned space.

Complete turnkey responsibility provides the owner with the assurance that the D/H Series system can be managed by Harris from system conception to final system start up.

A Word About Harris Environmental

Harris Environmental Systems has been a turnkey manufacturer

of environmental rooms for over forty years. We originally specialized in

low temperature refrigeration systems and the installation and design of

working cold rooms, incubators, and freezers utilized in hospitals and universities

for medical research. Since the late 1960’s we have specialized in

providing dry rooms and low humidity systems to meet the needs of manufacturers

of moisture sensitive and hygroscopic products. Today, in addition to our

cold rooms and incubators, we specialize in modular dry rooms, D/H Series

custom dehumidification systems, clean rooms, cycling chambers , and

archival storage vaults. The Environmental Room Division is complimented

by our Refrigeration Service Division. Our highly skilled pipefitters, carpenters

and electricians install, test, and start up all components to assure

a quality installation.

The Harris “Single Source Quality Guarantee”

Installing a field built up dehumidification system forces the client

to coordinate with a multitude of manufacturers and contractors. This

requires hours of planning, coordinating and equipment expediting to achieve

project completion. When a D/H Series is turnkey installed by Harris, we

coordinate and control the design, manufacturing, start up and installation.

We take the burden of working with several sources off your shoulders and

onto ours and provide you with an additional benefit – that the D/H

Series system and all mechanical components will meet your specs for humidity

and temperature control for one full year after start up.

Superior Design VS. Mediocre Design

The next step is yours! Humidity control is no joke

when thousands of dollars of product are lost to seasonal fluctuations, low

yields, and high maintenance and operating costs due to marginal system design.

You can call your local “friendly

contractor” who will attempt to build a dehumidification system and

hope that the result will meet your needs. Or, you can call the experts at

Harris Environmental Systems, who will design, build and guarantee that your

D/H Series system will maintain precise humidity and temperature requirements

critical to your application. If you can’t take the chance on mediocre

design, callus for a free consultation and proposal.

| Environmental

Rooms | Dry

Rooms | Clean

Rooms | Archival

Storage Vaults | |

Harris Environmental Systems, Inc. • 11 Connector Road • Andover, MA 01810 |

| tel: (978) 470-8600 • fax: (978) 475-7903 |