Sensible Heat Loads

The

difficulty of maintaining a specified room condition, uniformity and gradient

depends on the nature and size of heat loads even more than the tightness of

the specification.

The

difficulty of maintaining a specified room condition, uniformity and gradient

depends on the nature and size of heat loads even more than the tightness of

the specification.

In cold storage rooms, heat loads are small and relatively constant. Small, simple equipment can remove the loads since large temperature differences throughout the room are acceptable to the end user.

Environmental rooms have very dynamic, changing load characteristics, as well as having much tighter uniformity and gradient specifications. Consequently, it is essential to specify the load elements clearly because they have a major effect on room cost.

Unfortunately, load characteristics are the most difficult elements for the specifier to predict. The end user seldom knows precisely what operations will take place in the room, or what changes in use may occur over time. Given this reality, it is important for the end user to understand that either the room cost or the specified conditions must change if loads change between budgets and bids.

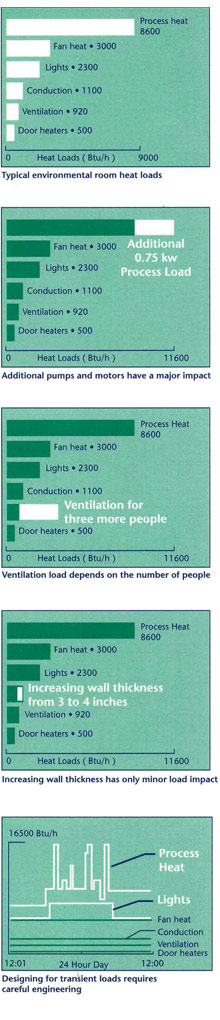

Some load changes will have a larger effect than others. The graphics at left show a typical load profile for an environmental room which must maintain a temperature of 4ºC with a uniformity of ±0.5ºC and a gradient of 1ºC. The room is built inside another building and the floor is insulated. It is further described as follows:

- 3” thick aluminum-clad urethane walls

- 12’W x 14’L x 9’-6”H (Outside dimensions)

- One occupant

- One door with anti-condensation heaters

- Four light fixtures, producing 100 foot-candles @ working height

- 20 cfm ventilation airflow

- Internal process load - 15 watts/sq. ft.

Process loads include small motors and pumps for laboratory equipment. These create the largest heat load if all are running simultaneously. In this room, the load is a relatively typical 15 watts per square foot. If the equipment is spaced evenly across the working surfaces, it will be quite simple to maintain specifications. However, if the load is concentrated at a single point--such as a large vessel containing warm liquid--it will be difficult to maintain uniformity. Later additions of process equipment or highly concentrated heat sources will significantly affect the system’s ability to meet specifications throughout the entire space.

Fans that circulate air through the room produce heat as well. Rooms with tighter uniformity and gradient specifications require large airflows. Therefore, the fans must be powerful and the cooling system must remove the heat produced by the fan motors.

Lighting load is much smaller than the equipment load, but still quite significant. This is another reason why storage rooms are less costly than environmental rooms--less illumination means less heat and smaller cooling systems.

Ventilation air is minimized to avoid excessive cooling costs. In this example, a small fan pulls ventilation air from the areas just outside the room. Occasionally it is necessary to take untreated air directly from outside the building, or from a central system. In this case the moisture and heat load can double, and the cooling equipment would have to be increased. Also, the ductwork necessary to convey air from a central system to the room is complex and comparatively costly to install.

Heat conduction through the walls transmits only a small part of the load, and changes in this area do not greatly affect the cost of the room. For instance, increasing the wall thickness to 4” only reduces the conduction load by 200 Btuh, and increasing the length of the room to 20 ft would only add 344 Btuh to the load.

In summary, heat loads that bear discussion with the end user include:

- Process loads

- Ventilation requirements

Other loads, while not insignificant, are less likely to cause major

cost problems if changed later in the project.

| Environmental

Rooms | Dry

Rooms | Clean

Rooms | Archival

Storage Vaults | |

Harris Environmental Systems, Inc. • 11 Connector Road • Andover, MA 01810 |

| tel: (978) 470-8600 • fax: (978) 475-7903 |